History

Nordic Structures is a company dedicated to engineered wood products for the construction industry. It creates future-oriented solutions for academic, commercial, industrial, infrastructure, institutional, multi-residential, recreational and residential projects.

With its sister company, Chantiers Chibougamau, Nordic Structures benefits from more than 50 years of expertise and innovation in wood transformation. The company is now integrating cross-laminated timber (CLT) into its product line. It also offers technical support to architects and engineers.

From the distribution of products to the realization of turnkey wooden structures, Nordic Structures distinguishes itself by its technical expertise and the quality of its products. It provides sustainable solutions that meet its customers’ expectations in terms of service, logistics and budget.

Project Information

Project Data

Location: Montreal, Quebec, Canada

Architectural firm: Saucier + Perrotte Architects http://saucierperrotte.com/

Wood Construction: Nordic Structures http://nordic.ca/

Fabrication: Chantiers Chibougamau http://chibou.com/

Volume of wood: 4000m3

Useful surface: 12 600m2

With its extraordinary dimensions of 110m long, 78m wide and 18m high, the new soccer stadium of the city of Montreal does not leave anyone indifferent.

This unique construction is to the credit of the architectural studio Saucier + Perrotte Architects, who created a roof made of a mesh of non-orthogonal beams that gives a very interesting perspective effect. Moreover, with the use of 4000m3 of Quebec black spruce, this construction has a very interesting carbon footprint that other materials cannot achieve.

The wood structure is the result of the work of Nordic Structures for the design and engineering part as well as Chantiers Chibougamau for the supply of wood and CNC manufacturing. The cadwork software contributed to the success of the project with the 3D modeling of the roof structure, the manufacturing and assembly plans as well as the development of the CNC machine data.

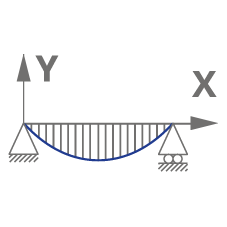

The interface between cadwork and the Leica Builder total station also allowed the accuracy of the metal supports to be checked before the 13 main beams of almost 70m length and 4m height were lifted. The main beams are box beams made of glued laminated timber and CLT panels, ensuring the aesthetics desired by the architect without penalizing the weight of the structure.

One of the challenges was the transmission of the tensile forces in the 3-part bottom chord. These forces are transmitted by a steel fitting attached to the glulam beams with screws that were developed specifically for this project.

This project is another example of successful collaboration between pioneering architects who take advantage of the many benefits of wood and state-of-the-art wood construction specialists.

Solutions

For this project, our client used the following solutions:

DOWNLOAD CADWORK

Test cadwork for 2 months before making your decision! After a 2-day training, you will receive a free 2-month trial version, including telephone support and all our services.